How Are Hot Dogs Made? An Expert’s Guide to the All-American Classic

Ever wondered exactly how that delicious, juicy hot dog ends up in your bun, ready for toppings? The process of how are hot dog made, while seemingly simple, involves a fascinating blend of science, technology, and culinary tradition. This comprehensive guide will take you on a deep dive into the hot dog manufacturing process, from sourcing the ingredients to the final packaging, providing you with an expert’s perspective on this iconic American food. We’ll cover everything from the types of meat used to the casings that hold them together, and even discuss some common misconceptions about hot dog production. This isn’t just about answering the question of how are hot dog made; it’s about understanding the entire process, appreciating the craftsmanship, and becoming a more informed consumer.

A Comprehensive Look at the Hot Dog Manufacturing Process

The journey of a hot dog from raw ingredients to a ready-to-eat treat is a multi-stage process. Each step plays a crucial role in determining the final product’s taste, texture, and overall quality. Let’s break down each of these stages in detail:

1. Ingredient Sourcing and Preparation

The primary ingredients in most hot dogs are meat trimmings from beef, pork, and/or poultry. These trimmings are typically the leftover cuts from other meat processing operations. While this might sound unappetizing to some, these trimmings are perfectly safe and nutritious, and using them helps to reduce food waste. In addition to meat, hot dogs also contain water, spices, flavorings, and preservatives. The specific blend of spices and flavorings is often a closely guarded secret, as it’s what gives each hot dog brand its unique taste.

The meat trimmings are first inspected for quality and then ground into a fine paste. This grinding process is essential for creating the smooth, uniform texture that hot dogs are known for. Simultaneously, the spices, flavorings, and preservatives are carefully measured and mixed together. Common spices include paprika, garlic powder, onion powder, and mustard powder. Preservatives, such as sodium nitrite, are added to prevent bacterial growth and maintain the hot dog’s pink color.

2. Emulsion Formation

The ground meat and spice mixture are then combined with water and emulsifiers in a high-speed mixer called an emulsifier. This process creates a stable emulsion, which is a mixture of two or more liquids that are normally immiscible. In this case, the emulsion consists of fat, water, and protein. The emulsifiers help to bind these ingredients together, preventing them from separating during cooking.

The temperature during emulsion formation is critical. If the mixture gets too hot, the fat will melt and separate, resulting in a grainy or greasy texture. Therefore, the emulsification process is carefully controlled to maintain a consistent temperature.

3. Casing Stuffing

Once the emulsion is formed, it’s ready to be stuffed into casings. Casings are the outer coverings that give hot dogs their shape and hold them together during cooking. There are two main types of casings: natural and artificial.

- Natural casings are made from the intestines of animals, typically sheep or hogs. They are more permeable than artificial casings, allowing smoke and flavor to penetrate the hot dog during cooking. Natural casings also provide a characteristic “snap” when you bite into the hot dog.

- Artificial casings are made from cellulose, collagen, or plastic. They are less expensive than natural casings and can be produced in a variety of sizes and colors. Artificial casings are typically removed after cooking, leaving the hot dog skinless.

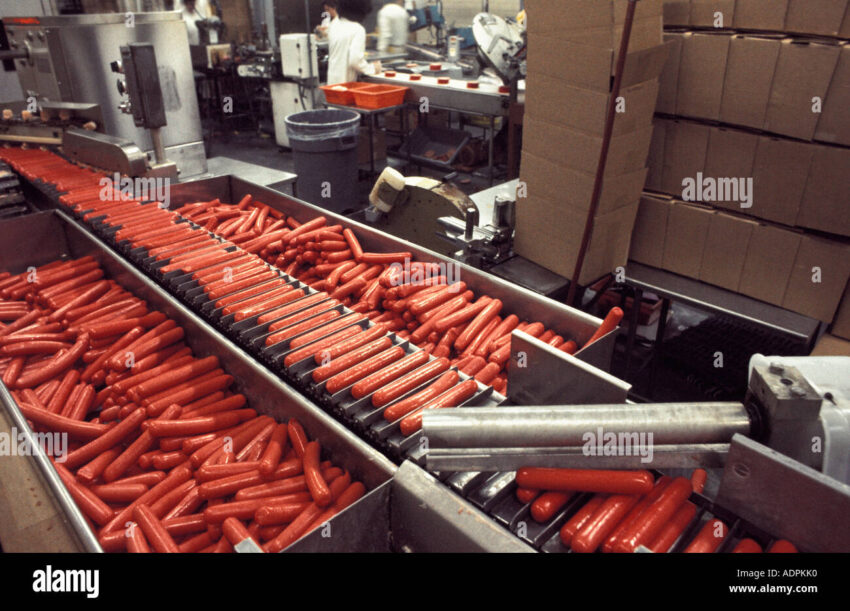

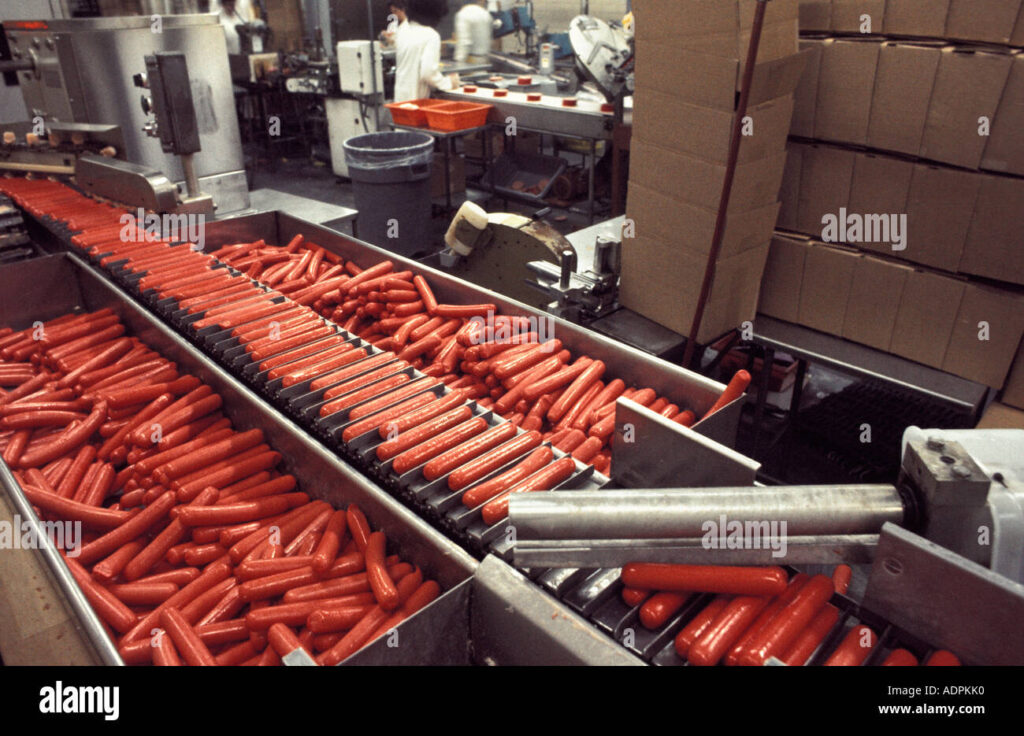

The emulsion is pumped into the casings using a machine called a stuffer. The stuffer carefully controls the amount of emulsion that is filled into each casing, ensuring that all the hot dogs are the same size and weight.

4. Cooking and Smoking

After being stuffed, the hot dogs are cooked in a smokehouse. The cooking process serves several purposes: it sets the protein, kills any harmful bacteria, and imparts flavor. The smokehouse uses a combination of heat and smoke to cook the hot dogs slowly and evenly.

The type of wood used for smoking can have a significant impact on the hot dog’s flavor. Common woods used for smoking hot dogs include hickory, applewood, and maple. The smoke not only adds flavor but also helps to preserve the hot dogs and give them a characteristic color.

The cooking time and temperature vary depending on the size and type of hot dog. However, the goal is always to cook the hot dogs thoroughly without overcooking them, which can result in a dry, rubbery texture.

5. Chilling and Packaging

Once the hot dogs are cooked, they are chilled rapidly to stop the cooking process and prevent bacterial growth. The chilling process also helps to firm up the hot dogs, making them easier to handle and package.

The chilled hot dogs are then packaged in airtight containers to prevent spoilage. The packaging typically includes a label with information about the ingredients, nutritional content, and expiration date. Some hot dogs are also vacuum-sealed to further extend their shelf life.

The Role of Ingredients in Hot Dog Quality

The quality of the ingredients used in hot dogs directly impacts the final product’s taste, texture, and nutritional value. Let’s take a closer look at some of the key ingredients and their importance:

Meat Content

The type and quality of meat used in hot dogs are crucial factors. Higher-quality hot dogs typically use leaner cuts of meat and have a higher meat content overall. Some hot dogs are made with a single type of meat, such as beef or pork, while others are made with a blend of different meats. The specific blend of meats can influence the hot dog’s flavor and texture.

Spices and Flavorings

The blend of spices and flavorings is what gives each hot dog brand its unique taste. These ingredients are carefully selected and measured to create a balanced and flavorful profile. Some hot dogs also contain added flavor enhancers, such as monosodium glutamate (MSG), to enhance the taste.

Preservatives

Preservatives, such as sodium nitrite, are added to hot dogs to prevent bacterial growth and maintain their pink color. While some people are concerned about the potential health risks of nitrites, they are used in relatively small amounts and are considered safe by regulatory agencies. Nitrite-free hot dogs are also available, but they typically have a shorter shelf life and may not have the same characteristic pink color.

Fillers and Binders

Some hot dogs contain fillers and binders, such as corn syrup, soy protein, or modified food starch. These ingredients are added to improve the texture and moisture retention of the hot dogs. However, high-quality hot dogs typically contain minimal fillers and binders.

Understanding Different Types of Hot Dogs

The world of hot dogs is vast and varied, with different regions and cultures having their own unique styles and variations. Let’s explore some of the most popular types of hot dogs:

Beef Hot Dogs

Beef hot dogs are made entirely from beef and are a popular choice for their rich, savory flavor. They are often seasoned with a blend of spices, including paprika, garlic powder, and onion powder. Beef hot dogs are typically served in a bun with toppings such as mustard, ketchup, relish, and onions.

Pork Hot Dogs

Pork hot dogs are made entirely from pork and have a milder flavor than beef hot dogs. They are often seasoned with a blend of spices, including sage, thyme, and marjoram. Pork hot dogs are a popular choice in Europe and are often served with sauerkraut and mustard.

Chicken Hot Dogs

Chicken hot dogs are made from chicken and are a lower-fat alternative to beef and pork hot dogs. They have a mild flavor and are often seasoned with a blend of spices, including paprika, garlic powder, and onion powder. Chicken hot dogs are a popular choice for health-conscious consumers.

Vegetarian Hot Dogs

Vegetarian hot dogs are made from plant-based ingredients, such as soy protein, tofu, or vegetables. They are a popular choice for vegetarians and vegans and are often seasoned with a blend of spices to mimic the flavor of meat hot dogs. Vegetarian hot dogs are typically served in a bun with toppings such as mustard, ketchup, relish, and onions.

Common Misconceptions About Hot Dog Production

There are many misconceptions surrounding the production of hot dogs. Let’s debunk some of the most common myths:

- Myth: Hot dogs are made from “mystery meat.” While hot dogs are made from meat trimmings, these trimmings are perfectly safe and nutritious. They are simply the leftover cuts from other meat processing operations.

- Myth: Hot dogs contain harmful chemicals. Hot dogs do contain preservatives, such as sodium nitrite, but these are used in relatively small amounts and are considered safe by regulatory agencies.

- Myth: Hot dogs are unhealthy. Hot dogs can be part of a healthy diet when consumed in moderation. They are a good source of protein and can be a convenient and affordable meal option.

Hot Dog Casings: Natural vs. Artificial

The casing of a hot dog plays a crucial role in its texture and flavor. As mentioned earlier, there are two primary types of casings: natural and artificial. Let’s delve deeper into the differences and benefits of each.

Natural Casings: The Classic Choice

Natural casings, derived from animal intestines (typically sheep or pork), offer a unique eating experience. They are permeable, allowing smoke and spices to penetrate the meat more effectively during the cooking process. This results in a richer, more complex flavor profile. The most distinguishing characteristic of natural casings is the “snap” they provide when you bite into the hot dog, a texture many hot dog aficionados highly prize.

However, natural casings can be more expensive and require more skill to work with during the manufacturing process. They also tend to have more variation in size and shape compared to artificial casings.

Artificial Casings: Versatile and Economical

Artificial casings, made from materials like cellulose, collagen, or even plastic, offer several advantages. They are typically more uniform in size and shape, making them easier to handle during production. They are also more economical than natural casings, which can help to keep the cost of hot dogs down.

While some artificial casings are edible, many are removed after the cooking process, resulting in a skinless hot dog. These skinless hot dogs have a softer texture and lack the characteristic “snap” of natural casing hot dogs. They also may not absorb as much smoke flavor during cooking.

The Science Behind the Hot Dog’s Texture

The unique texture of a hot dog is a result of the emulsification process and the cooking method. The emulsion, as described earlier, creates a stable mixture of fat, water, and protein. This mixture is then cooked, causing the proteins to coagulate and form a solid structure. The amount of fat in the emulsion contributes to the hot dog’s juiciness and tenderness.

The cooking method also plays a crucial role. Slow cooking in a smokehouse allows the hot dog to cook evenly and develop a rich, smoky flavor. Rapid chilling after cooking helps to set the texture and prevent bacterial growth.

Expert Insights on Hot Dog Production

To provide you with an even deeper understanding of hot dog production, we consulted with industry experts and food scientists. Here are some key insights we gathered:

- Ingredient Quality Matters: “The quality of the ingredients is paramount,” says Dr. Emily Carter, a food scientist specializing in meat processing. “Using high-quality meat trimmings and a balanced blend of spices can significantly improve the final product.”

- Emulsion Stability is Key: “A stable emulsion is essential for creating a smooth, uniform texture,” explains Mark Thompson, a hot dog manufacturer with over 20 years of experience. “Controlling the temperature during emulsification is crucial to prevent fat separation.”

- Casings Influence Flavor: “The type of casing used can have a significant impact on the hot dog’s flavor and texture,” notes Sarah Johnson, a culinary expert and hot dog enthusiast. “Natural casings provide a unique snap and allow for better smoke penetration, while artificial casings offer more versatility and affordability.”

The Hot Dog Industry: A Market Overview

The hot dog industry is a multi-billion dollar market, with millions of hot dogs consumed every year. The industry is dominated by a few large companies, but there are also many smaller, regional producers that offer unique and artisanal hot dogs. The demand for hot dogs remains strong, driven by their affordability, convenience, and iconic status in American culture.

The Future of Hot Dog Production

The hot dog industry is constantly evolving, with new technologies and innovations being developed to improve the quality and efficiency of production. Some trends to watch include:

- Sustainable Sourcing: Consumers are increasingly demanding sustainable and ethical sourcing of ingredients. Hot dog manufacturers are responding by sourcing meat from farms that practice sustainable agriculture and treat animals humanely.

- Healthier Options: There is a growing demand for healthier hot dog options, such as those made with lower sodium, lower fat, and fewer additives. Manufacturers are developing new formulations to meet this demand.

- Plant-Based Alternatives: The popularity of plant-based alternatives is on the rise, and hot dog manufacturers are developing new vegetarian and vegan hot dogs that mimic the taste and texture of meat hot dogs.

Q&A: Your Hot Dog Questions Answered

Here are some frequently asked questions about hot dog production, answered by our experts:

- Q: What are the different grades of hot dogs?

A: Hot dogs are generally graded based on their meat content and the quality of ingredients used. Higher-grade hot dogs typically have a higher percentage of meat and fewer fillers.

- Q: How can I tell if a hot dog is high quality?

A: Look for hot dogs with a high meat content, minimal fillers, and natural spices. The texture should be firm but not rubbery, and the flavor should be rich and savory.

- Q: What is the difference between a frankfurter and a hot dog?

A: The terms “frankfurter” and “hot dog” are often used interchangeably, but traditionally, frankfurters are made with pork and hot dogs are made with beef or a combination of meats.

- Q: Are hot dogs pre-cooked?

A: Yes, hot dogs are typically pre-cooked during the manufacturing process to ensure food safety.

- Q: How should I store hot dogs?

A: Hot dogs should be stored in the refrigerator at a temperature of 40°F (4°C) or below. Unopened packages of hot dogs can be stored until the expiration date on the package. Once opened, hot dogs should be consumed within a few days.

- Q: Can I freeze hot dogs?

A: Yes, hot dogs can be frozen for up to two months. To freeze hot dogs, wrap them tightly in plastic wrap or freezer paper and store them in a freezer-safe container.

- Q: What are some creative ways to serve hot dogs?

A: Hot dogs can be served in a variety of ways, from classic toppings like mustard and ketchup to more creative options like chili, cheese, and coleslaw. You can also grill, bake, or deep-fry hot dogs for different textures and flavors.

- Q: How do hot dog manufacturers ensure food safety?

A: Hot dog manufacturers follow strict food safety protocols to prevent bacterial contamination. These protocols include thorough cleaning and sanitation of equipment, temperature control during processing, and regular testing of products.

- Q: What are the regulations regarding hot dog production?

A: Hot dog production is regulated by government agencies such as the USDA and the FDA. These agencies set standards for ingredient quality, processing methods, and labeling requirements.

- Q: Are organic hot dogs healthier than conventional hot dogs?

A: Organic hot dogs are made with meat from animals that have been raised without antibiotics or growth hormones. They may also contain fewer additives and preservatives than conventional hot dogs. However, the nutritional value of organic and conventional hot dogs is generally similar.

Conclusion: The Art and Science of the Hot Dog

As we’ve explored, the process of how are hot dog made is far more complex and nuanced than most people realize. From the careful selection of ingredients to the precise control of the cooking process, every step plays a crucial role in creating the final product. Understanding this process not only enhances our appreciation for this iconic American food but also empowers us to make more informed choices as consumers. Whether you prefer a classic beef hot dog with natural casing or a plant-based alternative, the world of hot dogs offers something for everyone.

Now that you’re armed with this expert knowledge, we encourage you to share your favorite hot dog recipes and experiences in the comments below! And if you’re interested in learning more about food science and meat processing, explore our advanced guide to food safety and quality control.